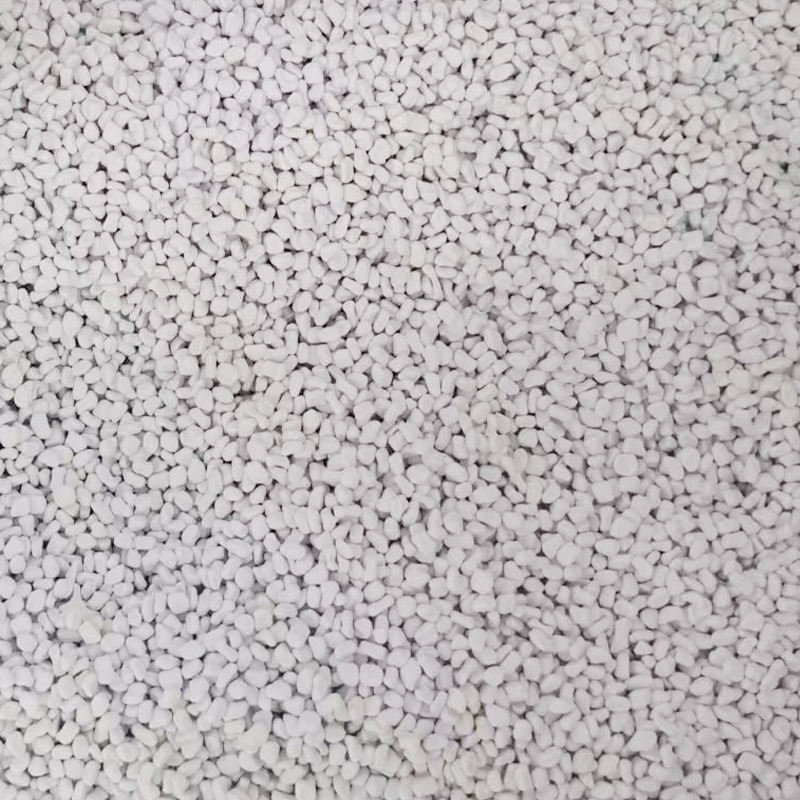

In plastic processing, filler masterbatch is widely used in polyolefin products such as PE and PP due to its low cost, uniform coloring, and good processability.

- +86-13705563540

0086-556-6881709 - 13705563540@qq.com

- No. 3 Jingyi Road, Tongcheng Shuangxin Industrial Park, Anqing City, Anhui Province