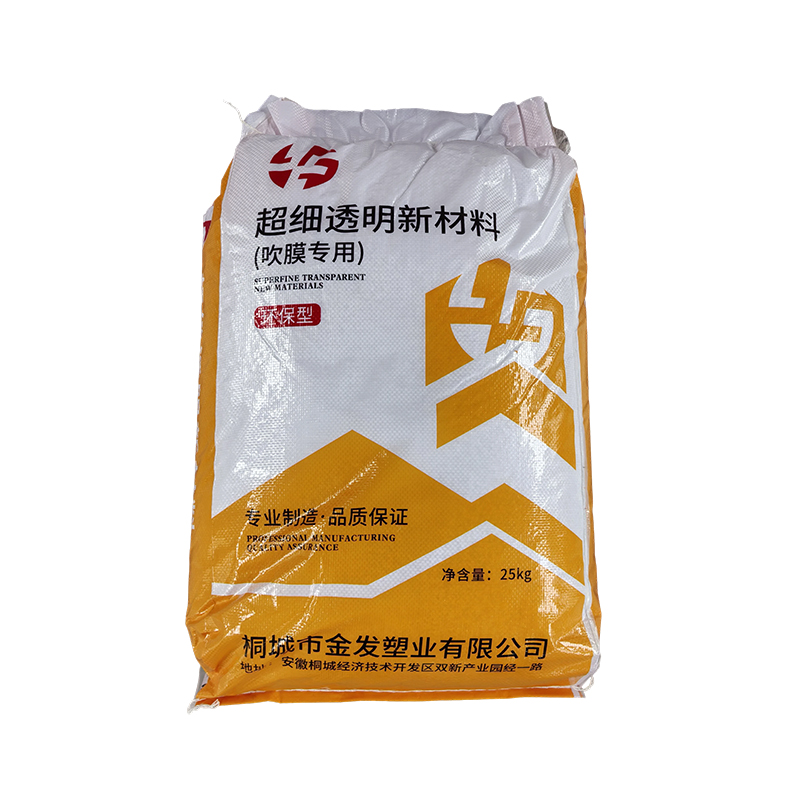

To solve this problem, transparent filling masterbatch was developed. Through a deep integration of materials science and precision manufacturing, it can give PE, PP, and other plastics vibrant colors while maintaining excellent high light transmittance,

- +86-13705563540

0086-556-6881709 - 13705563540@qq.com

- No. 3 Jingyi Road, Tongcheng Shuangxin Industrial Park, Anqing City, Anhui Province